INNOVATIVE SHEET METAL FABRICATION FOR UNMATCHED QUALITY

COMMITMENT TO DELIVERING QUALITY ON TIME, EVERY TIME

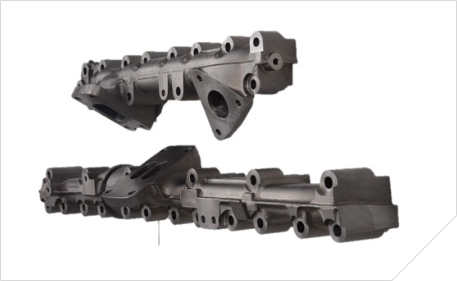

FABRICATION

Rabwin specializes in high-quality sheet metal fabrication with decades of experience. Our advanced technology ensures precision and durability in every weld. We use TIG & MIG welding and power press systems for complex components. Our expertise guarantees accuracy, consistency, and top-notch quality. Trust us for all your metal fabrication needs.

OUR MACHINERY

CNC Laser Cutting

Rabwin’s advanced CNC laser cutting ensures precision, high-quality cuts, and excellent repeatability. It handles intricate designs with accuracy, reducing material waste while enhancing productivity. Our machine supports a 4000 x 2000 mm bed, 5000W laser power, and cuts up to 25mm steel, 20mm stainless, and 12mm aluminium. Achieve smooth edges with minimal distortion for superior fabrication results.

MECHANICAL POWER PRESS

Our mechanical power press has a spacious 600 x 1000 mm bed with a pressing capacity of 100 tons. Designed for high-speed operations, it features a 500 mm daylight and a 100 mm stroke length, ensuring reliability and precision in metal shaping

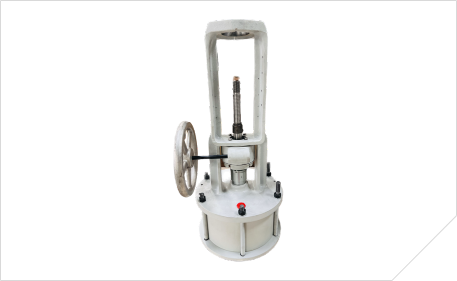

HYDRAULIC PRESS

Rabwin is equipped with a 600 x 600 mm bed, our hydraulic press offers a pressing capacity of 150 tons. It features an 800 mm daylight, 50-ton cushioning capacity, and a 500 mm cylinder stroke length for efficient and accurate metal forming.

ASSEMBLY

At Rabwin, our assembly process is designed for seamless integration and superior quality assurance at every production stage. Utilizing advanced technologies like laser-marked Data Matrix codes, we ensure precise product identification and full traceability. This streamlined workflow minimizes errors, optimizes logistics, and guarantees consistent, high-quality output.

KEY FEATURES

Our laser-engraved Data Matrix codes enable precise product identification and complete traceability, ensuring smooth tracking throughout the product lifecycle.

We capture critical data at every stage of assembly, ensuring compliance with industry standards while maintaining consistency and quality in the final product.

Our VMI system provides real-time inventory tracking, reducing lead times and ensuring a steady supply of premium components.

SPECIALIZED FEATURES

Assembly Automation

Assembly, automation & Fixtures for mobile phones

Biometric Authentication

Secure operation and setting selection using biometric verification.

DMC Code Scanning

Enables real-time online recording for accurate tracking.

Precision Fastening

Adopter tightening with Bosch/Rexroth electronic torque controllers, featuring online recording.

Length Control

Front and rear assembly equipped with LVDT for precise length measurement.

Leak Testing

ATEQ detectors ensure accurate leak testing with online data recording.

Poka Yoke Interlock

Prevents errors by blocking subsequent operations if the previous step is not validated through DMC.

Final Packing Automation

DMC reader integration enables real-time online data capture for accurate packing lists.

ASSEMBLY RANGE