RELIABLE HYDRAULIC CYLINDERS FOR DEMANDING APPLICATIONS

RELIABLE HYDRAULIC CYLINDERS FOR DEMANDING APPLICATIONS

FRONT END TELESCOPIC

Our front-end telescopic hydraulic cylinders are engineered for exceptional performance in heavy-duty applications. Designed to provide a long stroke while maintaining a compact retracted size, they are ideal for applications with space constraints. Built with high-strength materials and advanced sealing systems, they ensure reliable operation and longevity.

RABWIN

Front-End Cylinders with Eye

RABWIN

Front-End Cylinders with Eye

| Part No. | Description | Press (Bar) | Tipping Weight (tons) | Weight (kg) | Vol. (ltr) | Oil Inlet | K* (mm) | A* (mm) | B* (mm) | C (mm) | D (mm) | E (mm) | F (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RABFE-129-3630/03 | FET 129-3630/03-K1530-HCP | 250 | 43-59 | 137 | 40 | 1"SAE | 1530 | 1583 | 60 | 190 | 60 | 201 | 65 |

| RABFE-129-3880/03 | FET 129-3880/03-K1600-HCP | 250 | 43-59 | 143 | 42 | 1"SAE | 1600 | 1653 | 60 | 190 | 60 | 201 | 65 |

*Incl. 20mm pull out (p.o); tolerances -5 +30

| Part No. | Description | Press (Bar) | Tipping Weight (tons) | Weight (kg) | Vol. (ltr) | Oil Inlet | K* (mm) | A* (mm) | B* (mm) | C (mm) | D (mm) | E (mm) | F (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RABFE-149-3880/03 | FET 149-3880/03-K1644-HCP | 190 | 47-68 | 168 | 66 | 1"SAE | 1644 | 1697 | 60 | 190 | 60 | 201 | 65 |

| RABFE-149-4980/04 | FET 149-4980/04-K1530-HCP | 190 | 45-60 | 182 | 63 | 1"SAE | 1530 | 1583 | 60 | 190 | 60 | 201 | 65 |

*Incl. 20mm pull out (p.o); tolerances -5 +30

| Part No. | Description | Press (Bar) | Tipping Weight (tons) | Weight (kg) | Vol. (ltr) | Oil Inlet | K* (mm) | A* (mm) | B* (mm) | C (mm) | D (mm) | E (mm) | F (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RABFE-169-4505/04 | FET 149-3880/03-K1644-HCP | 190 | 47-68 | 168 | 66 | 1"SAE | 1644 | 1697 | 60 | 190 | 60 | 201 | 65 |

| RABFE-169-4825/04 | FET 149-4980/04-K1530-HCP | 190 | 45-60 | 182 | 63 | 1"SAE | 1530 | 1583 | 60 | 190 | 60 | 201 | 65 |

| RABFE-169-5200/04 | FET 149-4980/04-K1530-HCP | 190 | 45-60 | 182 | 63 | 1"SAE | 1530 | 1583 | 60 | 190 | 60 | 201 | 65 |

| RABFE-169-5400/05 | FET 149-4980/04-K1530-HCP | 190 | 45-60 | 182 | 63 | 1"SAE | 1530 | 1583 | 60 | 190 | 60 | 201 | 65 |

*Incl. 20mm pull out (p.o); tolerances -5 +30

Accessories

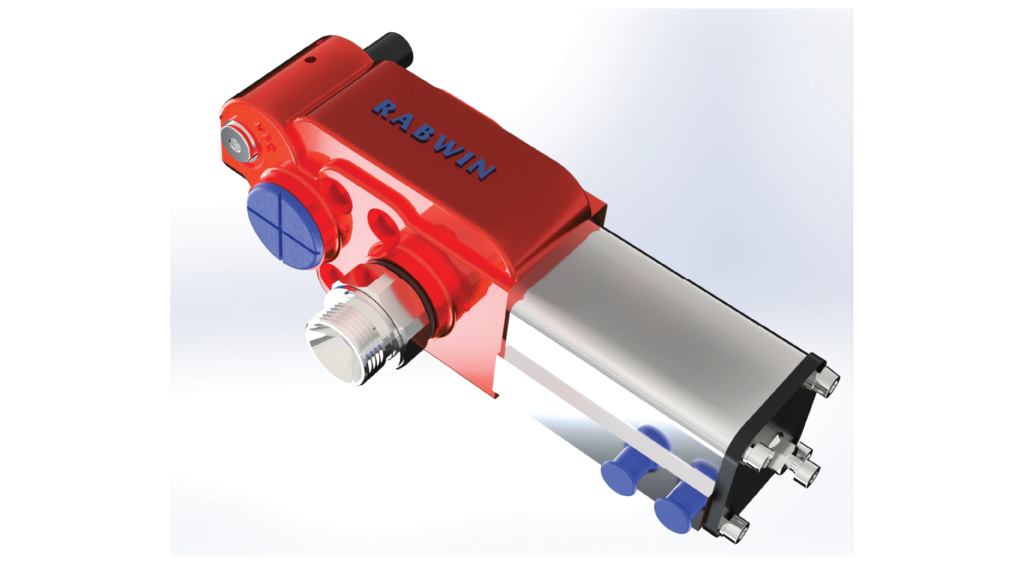

Tipping Valve 220 LPM SAE Mounted

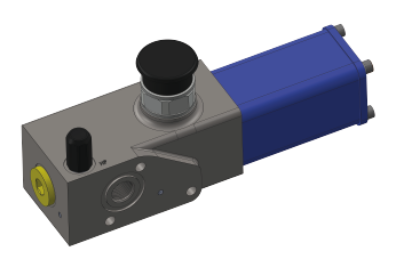

Tipping 220 Valve Tank Mounted

Front End Telescopic

Under body tipping

Rabwin Industries specializes in manufacturing underbody telescopic hydraulic cylinders designed for efficient and reliable performance in tipping applications. Our cylinders are engineered for compact underbody mounting, enhancing vehicle stability and maneuverability. With precision machining and high-quality materials, we ensure durability and optimal functionality for various industrial needs.

| Parameter | RABWIN DATC201 | RABWIN DATC0273 | RABWIN DATC0236 | RABWIN DATC0062 | ||||

|---|---|---|---|---|---|---|---|---|

| Stage 1 | Stage 2 | Stage 1 | Stage 2 | Stage 1 | Stage 2 | Stage 1 | Stage 2 | |

| A (Cylinder Closed Length, mm)* | 890 | 872 | 965 | 1220 | ||||

| B (Rod end ID, mm) | 35 | 40 | 40 | 40 | ||||

| C (Bore end ID, mm) | 38 | 40 | 40 | 40 | ||||

| D (Bore end width) | 130 | 145 | 145 | 145 | ||||

| E (Rod end width) | 77 | 75 | 75 | 75 | ||||

| F (Bore end-port size) | M22x1.5 | M22x1.5 | M22x1.5 | M22x1.5 | ||||

| G (Rod end-port size) | M22x1.5 | M22x1.5 | M22x1.5 | M22x1.5 | ||||

| Number of stages | 2 | 2 | 2 | 2 | ||||

| Cylinder fully opened length (mm) | 2075 | 1897 | 2190 | 2950 | ||||

| Stage wise stroke (mm) | 590 | 615 | 505 | 540 | 605 | 640 | 858 | 892 |

| Total Stroke (mm) | 1205 | 1045 | 1245 | 1750 | ||||

| Bore Sizes (mm) | 110 | 80 | 120 | 90 | 120 | 90 | 120 | 90 |

| Rod Sizes (mm) | 93 | 60 | 105 | 72 | 105 | 72 | 105 | 72 |

| Oil Volume (Litre) | 3.97 | 1.73 | 5.68 | 3.42 | 6.82 | 4.06 | 9.68 | 5.67 |

| Total Oil Volume | 5.7 | 9.1 | 10.88 | 15.35 | ||||

| Max Thrust @90° (kgf) | 17108 | 9049 | 18095 | 10178 | 18095 | 10178 | 20360 | 11452 |

| Working Pressure (Bar) | 180 | 160 | 160 | 180 | ||||

| Mounting | Clevis+ Rodeye | Clevis+ Rodeye | Clevis+ Rodeye | Clevis+ Rodeye | ||||

| Weight of Cylinder (kgs) | 55 | 53 | 57 | 76 | ||||

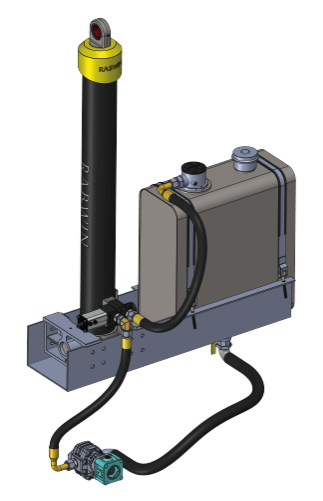

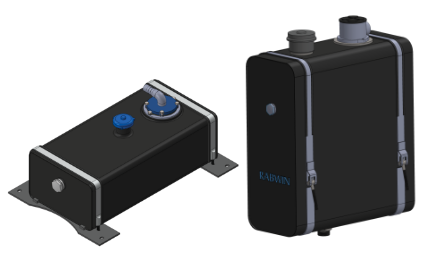

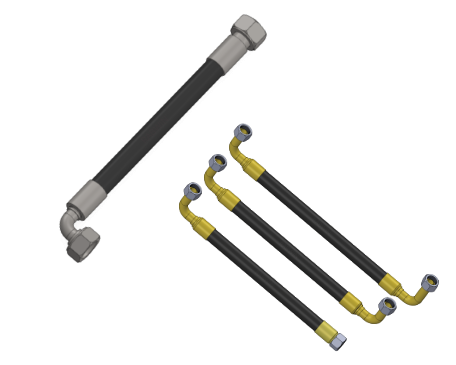

Accessories

DCV (Diectional Control Valve)

Hydraulic Tanks

Hydraulic Hoses

TIE ROD

The RABWIN Tie-Rod Cylinder delivers exceptional performance for agricultural, construction, transportation, and recycling applications. With extended clevis, SAE O-ring ports, and reliable testing, it is available in various bore sizes and strokes, backed by a strong warranty and custom color options.

| Bore | A* | C | H | I | M | P | Q | R** | S | T |

|---|---|---|---|---|---|---|---|---|---|---|

| 2.000(50.8) | 10.250(260.4) | 3/8” NPT | 1.165(29.6) | 1.165(29.6) | 2.000(50.8) | 0.394(10) | 1 1/8-12 UNF |

1.000(25.4) | 2.000(50.8) | 2.000(50.8) |

| 2.500(63.5) | 10.250(260.4) | 3/8” NPT | 1.165(29.6) | 1.165(29.6) | 2.000(50.8) | 0.394(10) | 1 1/8-12 UNF |

1.000(25.4) | 2.000(50.8) | 2.000(50.8) |

| 3.000(76.2) | 10.250(260.4) | 1/2” NPT | 1.165(29.6) | 1.165(29.6) | 2.000(50.8) | 0.500(12.7) | 1 1/4-12 UNF |

1.000(25.4) | 2.000(50.8) | 2.270(57.7) |

| 3.500(88.9) | 10.250(260.4) | 1/2” NPT | 1.165(29.6) | 1.165(29.6) | 2.000(50.8) | 0.551(14) | 1 1/4-12 UNF |

1.000(25.4) | 2.270(57.7) | 2.270(57.7) |

| 4.000(101.6) | 10.250(260.4) | 1/2” NPT | 1.165(29.7) | 1.165(29.7) | 2.000(54.0) | 0.630(16) | 1 1/4-12 UNF |

1.000(25.4) | 2.270(57.7) | 2.270(57.7) |

WELDED CYLINDERS

RABWin Welded Cylinder features a forged steel base and screw-in gland for a compact profile. Designed for agricultural, construction, and transportation equipment, it offers enhanced strength and flexibility with a 2” clevis and SAE O-ring ports for easy hookup. Each cylinder is tested at 1.5 times its working pressure for reliability and is available in bore sizes from 1.5” to 4” and strokes from 4” to 48

| BORE | A* | C | D | H | I | K | L | M | N | O | Q | R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.500(38.10) | 10.250(260.35) | SAE 6 | 0.75(19.05) | 0.787(19.99) | 0.787(19.99) | 2.125(53.98) | 0.906(23.01) | 0.922(23.42) | 2.126(54.00) | 0.905(19.99) | NA UNF |

0.765(19.43) |

| 2.000(50.8) | 10.250(260) | SAE 8 | 1.125(28.6) | 1.126(28.60) | 1.165(29.59) | 1.877(47.68) | 1.000(25.4) | 1.044(26.52) | 2.125(54.0) | 1.000(25.4) | 1 1/8-12 UNF |

1.011(25.7) |

| 2.500(63.5) | 10.250(260) | SAE 8 | 1.250(31.8) | 1.134(28.80) | 1.165(29.59) | 2.000(50.80) | 1.000(25.4) | 1.044(26.52) | 2.125(54.0) | 1.000(25.4) | 1 1/8-12 UNF |

1.011(25.7) |

| 3.000(76.2) | 10.250(260) | SAE 8 | 1.500(38.1) | 1.134(28.80) | 1.165(29.59) | 2.18(55.37) | 1.132(28.75) | 1.310(33.27) | 1.875(47.6) | 1.000(25.4) | 1 1/4-12 UNF |

1.011(25.7) |

| 3.500(88.9) | 10.250(260) | SAE 8 | 1.750(44.5) | 1.134(28.80) | 1.165(29.59) | 2.313(58.75) | 1.132(28.75) | 1.311(33.3) | 1.875(47.6) | 1.000(25.4) | 1 1/4-12 UNF |

1.011(25.7) |

| 4.000(101.6) | 10.250(260) | SAE 8 | 2.000(50.8) | 1.134(28.80) | 1.165(29.59) | 1.185(30.09) | 1.132(28.75) | 1.674(42.52) | 1.750(44.5) | 1.250(31.75) | 1 1/4-12 UNF |

1.011(25.7) |